Benefits of transformer oil filtration machine

Introduction

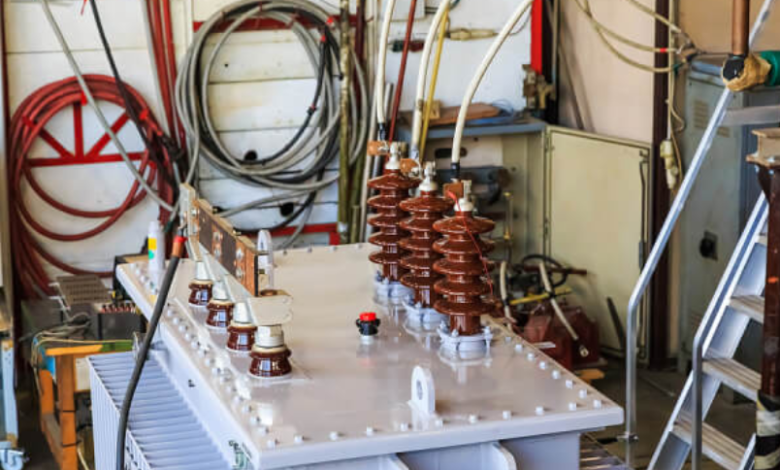

Transformer oil plays a critical role in ensuring the efficient performance and longevity of power transformers. It serves as an insulating medium and also dissipates heat generated during transformer operation. However, over time, transformer oil can become contaminated with moisture, gases, and solid particles, which degrade its insulating properties. This contamination can lead to transformer failure if not addressed promptly. A transformer oil filtration machine is an essential tool used to purify and restore the quality of transformer oil, thereby enhancing the reliability and safety of electrical equipment.

What is a transformer oil filtration machine?

A transformer oil filtration machine is specialized transformer oil filtration machine equipment designed to remove impurities from transformer oil. It works by filtering out water, gases, sludge, and other contaminants that accumulate during transformer operation. These machines use techniques such as vacuum dehydration, degassing, and fine filtration to improve the oil’s dielectric strength and extend its service life.

Why is transformer oil filtration important?

Contaminated transformer oil can cause serious problems such as insulation breakdown, overheating, and even catastrophic failure of transformers. Moisture reduces the oil’s dielectric strength, while dissolved gases indicate faults like arcing or overheating within the transformer. Solid particles and sludge can clog cooling systems and damage internal components. Regular filtration of transformer oil helps:

- Remove moisture and dissolved gases

- Eliminate solid contaminants

- Restore dielectric properties

- Prevent corrosion and sludge buildup

- Extend transformer and oil life

Implementing routine filtration reduces maintenance costs and avoids unplanned outages.

Key components of transformer oil filtration machine

A typical transformer oil filtration machine consists of several critical components:

- Heating system: Preheats the oil to reduce viscosity and improve impurity separation.

- Vacuum chamber: Removes dissolved moisture and gases under low pressure.

- Filtration units: Multiple stages of filters remove solid particles and sludge.

- Pump system: Circulates oil through the machine efficiently.

- Control panel: Monitors temperature, vacuum level, and operational parameters for safe and effective purification.

These components work together to ensure thorough purification.

How does a transformer oil filtration machine operate?

The operation process involves several steps:

- Heating: Oil is heated to around 60-80°C to lower viscosity.

- Vacuum dehydration: Heated oil enters a vacuum chamber where moisture and gases are extracted.

- Filtration: Oil passes through fine filters that trap particles and sludge.

- Degassing: Remaining dissolved gases are removed to restore oil purity.

This cycle continues until the oil reaches the desired quality standards suitable for reuse.

Applications of transformer oil filtration machine

These machines are widely used in:

- Power plants: To maintain transformers that operate under high voltage and load conditions.

- Electrical substations: For routine maintenance and oil quality restoration.

- Manufacturing industries: Where large transformers support heavy machinery.

- Renewable energy facilities: To protect transformers in wind and solar power installations.

- Maintenance service providers: For on-site oil purification and transformer upkeep.

Their ability to ensure transformer reliability makes them indispensable in electrical infrastructure.

See also: Understanding Life Insurance in Today’s World

Advantages of using a transformer oil filtration machine

Cost-effectiveness

Purifying transformer oil using a filtration machine reduces the need for frequent oil replacement, saving significant expenses on oil procurement and disposal.

Enhanced transformer performance

Clean oil ensures better insulation and cooling, preventing overheating and prolonging transformer lifespan.

Environmental benefits

Recycling transformer oil minimizes hazardous waste generation and reduces environmental pollution.

Reduced downtime

Maintaining oil quality through filtration helps prevent unexpected transformer failures, ensuring continuous power supply.

Improved safety

Removing moisture and gases decreases the risk of electrical faults and fire hazards.

Maintenance tips for transformer oil filtration machines

To keep the machine operating efficiently:

- Regularly replace filters to prevent clogging.

- Monitor vacuum and temperature settings to ensure proper operation.

- Inspect seals, valves, and pipelines for leaks or damage.

- Clean the heating elements and vacuum chambers periodically.

- Schedule professional servicing for calibration and troubleshooting.

Proper maintenance maximizes machine lifespan and purification effectiveness.

Innovations in transformer oil filtration technology

Modern transformer oil filtration machines feature:

- Automated control systems with real-time monitoring

- Energy-efficient designs reducing power consumption

- Portable and modular models for on-site service

- Advanced filtration media improving impurity removal

- Remote diagnostics and IoT integration for predictive maintenance

These advancements make oil filtration safer, faster, and more reliable.

Selecting the right transformer oil filtration machine

When choosing a machine, consider:

- The volume of oil to be processed

- Required purification speed and filtration precision

- Compatibility with different transformer oil types

- Level of automation and ease of operation

- After-sales support and availability of spare parts

Matching the machine to operational needs ensures effective oil purification.

Conclusion

A transformer oil filtration machine is a vital asset in maintaining the health and performance of power transformers. By effectively removing contaminants, it safeguards transformers from failures and extends their service life. Investing in reliable filtration equipment and following regular maintenance practices not only reduces operational costs but also enhances electrical system safety and sustainability. As transformer technology advances, so do filtration machines, offering improved features that meet the growing demands of the power industry.